Energy and Industry

European energy markets are currently in a state of emergency. EU faces the effects of a major unbalance in energy offer & demand, which is driving prices sky-high.

In the year 2021 alone, the cost of a megawatt per hour (MWh) climbed from 33.96€ to 111.96€ (Omie) - a trend that is still ongoing in 2022, and severely impacts the industrial ecosystem in the region, a sector that represents 25% of the overall national energy consumption.

Good news is, according to IDAE, spanish industry has enormous potential for energy savings.

In this context, what are the steps towards improving energy efficiency on your plant?

Applying the estándar de gestión energética ISO 50001 can be a good starting point.

ISO 50001, what is it and why adopt it?

It is the energy management standard most frequently used in the world (Aenor). ISO 50001 acts as guide for your company, providing you with tools to identify the activities consuming the most energy, and therefore posing a greater cost. Once identified, a plan is put in place to minimize and drive down energy consumption.

Companies adopting this norm achieve:

- Immediate ROI. Energy costs savings decrease direct operational costs, as well as certain indirect costs. In many cases, savings of up to 41% in energy consumption have been recorded.

- Sustainability: carbon footprint reduction.

- Regulatory / normative compliance.

- Understanding and control on the amount of energy consumed in every process.

- Improved risks management: boosts resilience due to reducing dependence on fossil fuel-based energy, prone to wild fluctuations in prices and availability.

How to apply an energy management standard?

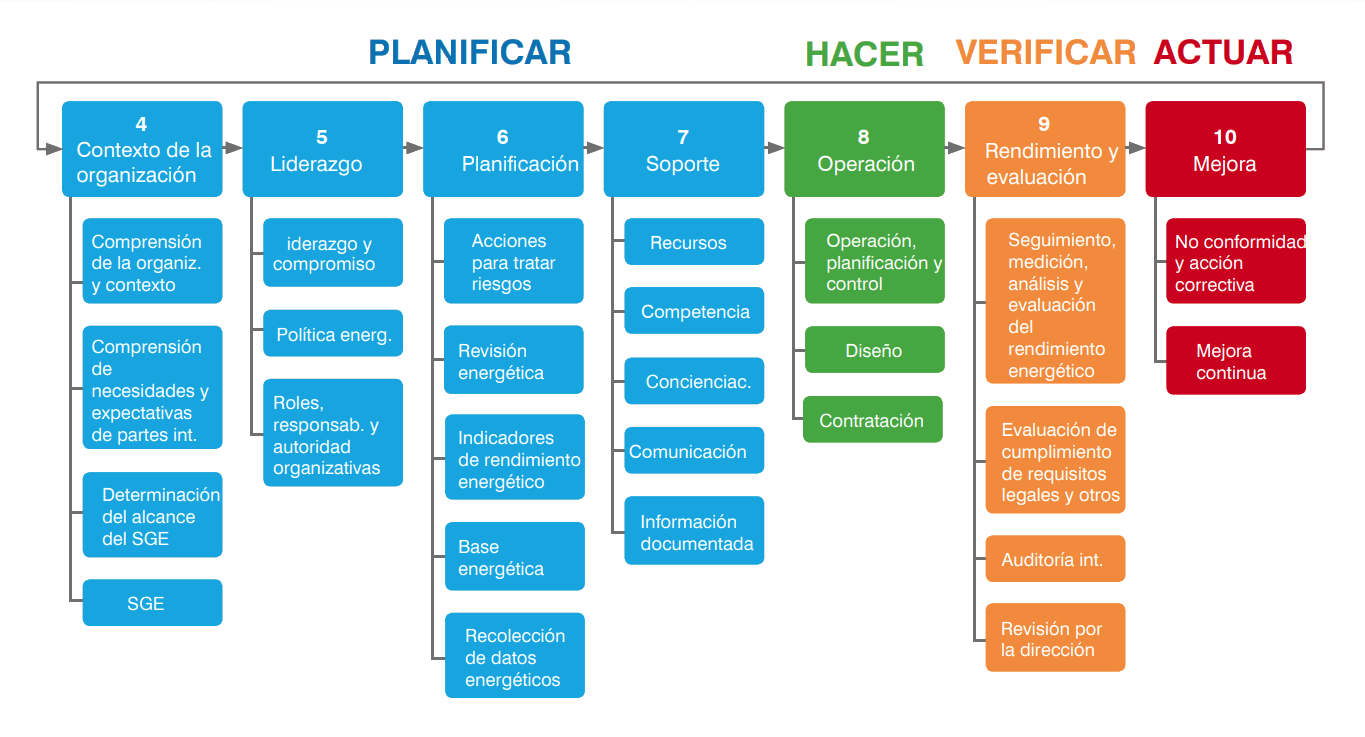

Same as other ISO norms, the energy management system ISO 50001 is based in the framework of "plan, do, verify, and act" (continuous improvement cycle). As defined by the Energy Sustainability Agency:

:

- Plan: focuses on understanding the behaviour of energy across your organization. This helps in spotting trends, energy usage, goals, actions and controls.

- Do: seeks to implement action plans based on data analysis in order to boost your energy performance.

- Verify: consists on monitoring and measuring processes and products, according to the goals and key features of your operations, as well as reporting on results.

- Act: is the making of decisions towards continuously improving your energy performance based on results.

ISO 50001 Diagram (source: Nqa, Global certification organism)

Following, a summary of the steps to follow in order to implement an energy management system on your company:

The first step is to carry out an exhaustive revision of energy usage and other aspects impacting positively or negatively on your energy performance. For instance: comprehension of requirements and expectations of stakeholders, leadership commitments and energy-related policies.

Once the context is defined, goals and specific energy milestones are set. The most common goals are usually driving down energy costs and better allocation thereof.

-

Revision of energy and definition of indicators

Energy revision is the analysis of energy efficiency, usage and consumption, based on data and other information. The aim is to identify significant energy uses and opportunities for improvement of energy performance.

The first step of this revision consist in identifying energy sources in your company, to later gather consumption data from each source. Some indicators to measure can be:

- Kilowatt per hour (kWh) consumed in each location.

- kWh per final product unit produced.

- kWh per number of personnel

- kWh per square meter of utilised office space.

This norm makes it very clear that the EMS (Energy Management System) must be data-driven.

To carry out this plan, it is necessary to unify human resources, technology, data gathering infrastructure, etc.

For starters, your company requires a system able to collect energy data from your equipment and production lines. At savvy, we have the conviction that this data collection must be simple, and for this, we obtain energy data directly from existing systems on your plant, or through different measuring devices.

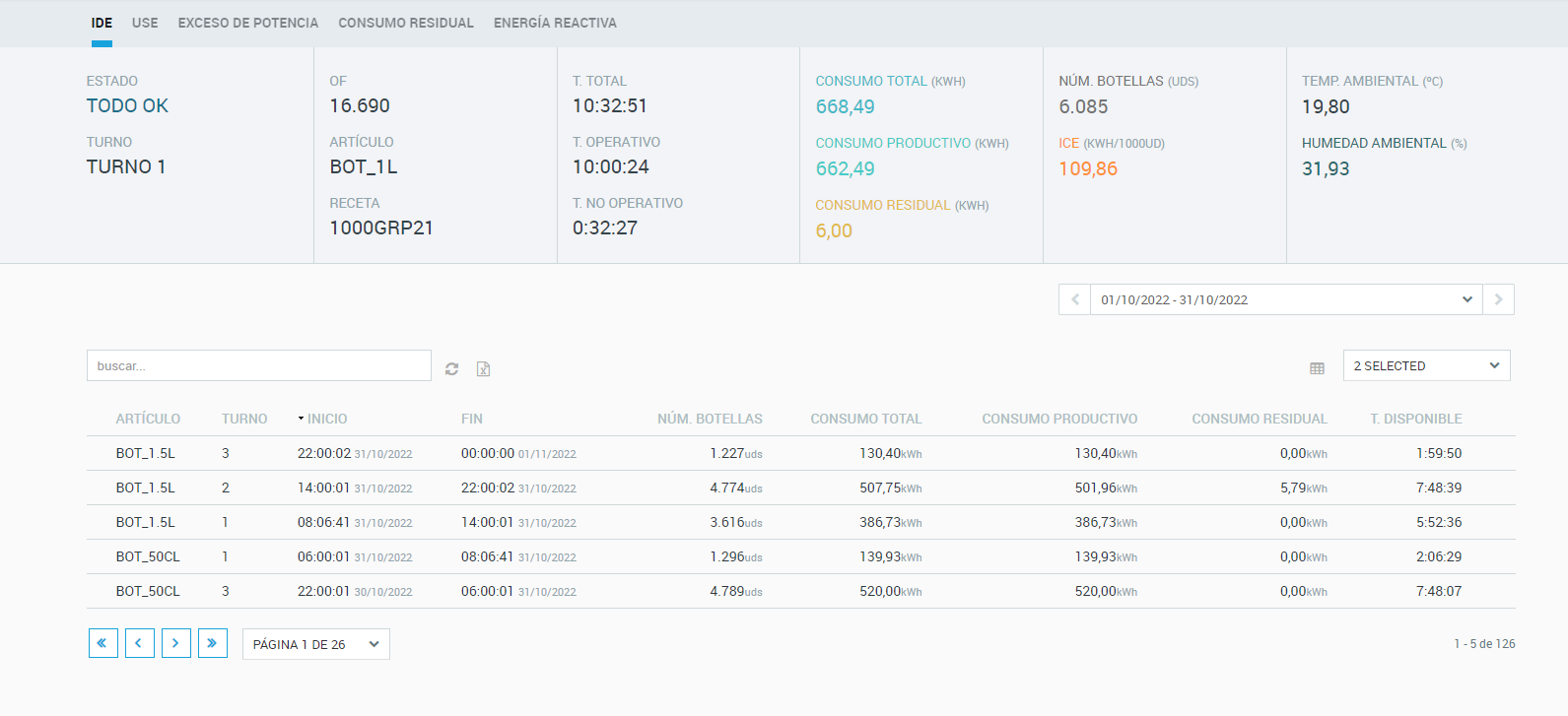

Once collected, it is convenient to visualize data from a single place for later analysis and extracting insights. For this purpose, Savvy emplys a platform for energy management that displays data collected from various sources in real time. This tool showcases:

- Energy consumption per article, shift, product, etc. to identify deviations and anomalous behaviour causing overall higher consumption in your company.

- Excess power in order to detect inefficiencies in machines or processes.

- Residual consumption, that is, detect every component consuming energy, regardless of them being currently producing / used.

- Excess reactive energy to avoid economic sanctions and penalties.

The aim here is for you to understand consumption of your machines and components for later optimization. Besides, factoring in the set goals, this smart tools reflects, based on current data, whether your will be able to meet your targets, or if corrections need to be made.

-

Evaluation and improvement

As mentioned above, there can be no improvement without measurement. That's why the norm specifies the minimum requirements your organization must control and measure:

- Efectiveness of action plans in achieving energy related goals and targets.

- EnPI(s) - Energy Performance Indicators.

- SEU (Significant Energy Usage) operation

- Expected vs. actual energy consumption.

How can Savvy assist you in improving energy efficiency on your plant?

Savvy's role is to provide your company with a tool on which you can base your planning and revise whether the set energy goals are met. For this, we have solutions that can:

- Obtain precise data on electrical consumption (and complementary non-electrical, such as waterm, CO2, etc.) from machines and components.

- Unify and coalesce said data in control panels and dashboards, displaying real time information.

- Analyze said information in order to improve energy performance.

These tools have been tested extensively by customer from various sectors, all of them with wildly varying energy needs. For this reason, they have evolved into a flexible, easy to install and use system, so that your efforts are not geared towards collection and management of data, but towards optimization of the same.

Grants

In the following link you may check at a glance the latest news on grants for energy efficiency from every Autonomous Community. https://www.aenor.com/certificacion/subvenciones-en-certificacion

REQUEST DEMO